The Conveyor Belt Cleaning System Explained

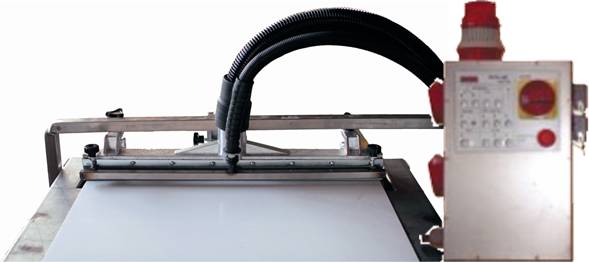

The Conveyor Belt Cleaning System is a steam cleaning device that has been developed to improve various standards associated with traditional conveyor belt cleaning methods. Attaching to a range of Tecnovap steam vacuum machines the Conveyor Belt Cleaner uses the power of continuous superheated dry steam and vacuum to hygienically clean and dry conveyor belt systems.

The Conveyor Belt Cleaning System can be used as either a permanently fixed intergrated unit or a portable mobile unit. This setup usually depends on whether there is a single conveyor belt or multiple conveyor belts that require cleaning. Most commonly portable units are required as many single conveyor belts do not have space for a permanently fixed unit and larger conveyors often have multiple change over points.

Quality Conveyor Belt Cleaning

Ideal for use in industries like food processing, pharmaceutical and manufacturing where conveyors need hygienic cleaning on a daily basis.

Ideal for use in industries like food processing, pharmaceutical and manufacturing where conveyors need hygienic cleaning on a daily basis.

Compared with traditional methods the Conveyor Belt Cleaning System is much faster and easier.

Advantages

Traditionally cleaning of conveyor belts has been regarded as an very laborious task that requires lots of time and physical effort; especially in extreme cases where conveyor need to be dismantled to clean. The Conveyor Belt Cleaning System on the other hand actually enables conveyor belts to be cleaned to a higher and more consistent standard whilst in place and operating; therefore saving hours/days of manual labour time.

In addition to time saving the Conveyor Belt Cleaner also reduces both water and chemical usage. This is possible through the use of continuous 94% superheated dry steam that requires less than 15lt of water per hour. Extra high +180°C steam temperatures produced by Tecnovap steamers also sanitise most surfaces on contact eliminating the need for most chemical disinfectants.

The added benefit of vacuum extraction leaves flat conveyors in a mostly dry state and immediately ready for use. This vacuum extraction combined with low water usage also makes the CCSS ideal for use on conveyor belts in areas without built in drainage.

Popular Applications

The JetSteam Tosca is an ideal cleaning solution for small commercial facilities or domestic environments that require shorter periods of cleaning. Providing up to 90 minutes of continuous steam a Tosca can be used to clean floors, walls, ceiling, windows, bathrooms, bedrooms, kitchens, beds, upholstery, curtains and a whole lot more.

Food Processing Plants

• Sanitise Conveyor

• Remove food build up

• Speed clean and sanitise other food processing equipment like benches, machinery and ovens.

Pharmaceutical

• Sanitise Conveyor

• Vacuum dust

• Deep clean hard to reach areas and other equipment.

Unique Features of the Conveyor Belt Cleaning System

165-180°C Dry Steam

165-180°C superheated dry steam is great for sanitising the conveyor belt surface and cutting through hard to clean soiling like oils and fats.

Portable or Intergrated

The Conveyor Belt Cleaning System can be used as a fixed system for cleaning a single conveyor or as a portable system for cleaning multiple conveyors.

Continuous Steam

The steam generators that power the Conveyor Belt Cleaning System all feature continuous steam production and have large water capacities.

Control Box

The electronic Control Box is used to regulate the amount of steam released onto the conveyor belt. The unit can be mounted on the conveyor or on the steam generator.

94% Dry Steam

The JetVac / Steam Box steam generators largely reduce water use by producing 94% dry steam that requires only about 15Lt of water per hour.

Conveyor Systems

The Conveyor Belt Cleaning System can be used to effectively and efficiently clean a variety of different style and different sized conveyor belts.

Included Accessories

The CCSS comprises of four main components:

- Standard 600mm Mountable Squeegee

- Electronic Control Box

- 2.5m Vacuum Hose

- Steam Bacchus Hose 12P

* Suitable Tecnovap steam vacuum system is not included and must be purchased separately.

Recommended Steam Generators

The Conveyor Belt Cleaning System works well with a variety of Tecnovap steam vacuum machines exclusively available in Australia through the Duplex Cleaning Machines distribution network. Ideal steam vacuum units include:

Standard Accessories for the JetVac

Kit July:

• Steam Hose

• 2 x Extension Tubes

• Detailing Lance

• Large Triangle Brush

• Large Rectangle Brush

• Round Stainless Brush

• Steel Pad

• Small Stainless Brush

• Small Brass Brush

Kit Radames:

• Steam/Vac Hose

• 2 x Extension Tubes

• Detailing Lance

• Floor Tool

• Floor Squeegee

• Floor Brush

Technical Specifications

| Specifications | Steambox Mini | Steambox Pro 3 phase | Steambox Industrial 3 phase |

|---|---|---|---|

| Pressure (Bar) | 6 | 10 | 10 |

| Water Storage (L) | 11 | 27 | 40 |

| Steam Temp (°C) | 165 | 180 | 180 |

| Continuous Steam | yes | yes | yes |

| Hot water / Chemical Injection | yes | yes | yes |

| Chemical Injection Temp (°C) | 125 | 145 | 145 |

| Recovery Vacuum Drum (L) | 14 | 14 | 35 |

| Machine Weight (Kg) | 30 | 40 | 140 |

| Max power (W) | 3650 | 4850 | 13900 |